During the Covid-19 pandemic, the demand for factory automation, and unmanned and labor-saving operations has been increasing. Investment in the introduction of robots and automation of manufacturing equipment has further accelerated. Higher speed and higher precision servo motor control are indispensable for improving productivity and product quality in the automation of such robots and manufacturing equipment. Factory automation is increasing the demand for functional safety compliance. The establishment of an autonomous production system that enables mass customization providing necessary products to the necessary people at the time they needed, and in the necessary quantities has become necessary due to the rapid fluctuations in demand during the pandemic. Industrial Ethernet for production equipment in factories and Time-Sensitive Networking (TSN) for the integration of IT and OT are indispensable elements in building an autonomous production system.

It has been common to increase the number of components to achieve high performance and multifunctionality in such devices. However, since the recent tight supply and demand situation for semiconductors, increasing the number of components increases the risk of issues to procure the components, which can hamper smooth product development and market release. We need to promote the development of high-performance, multifunctional products without increasing the number of components to minimize such risks.

Renesas launches the RZ/T2M microprocessor that meets these needs and is ideal for servo motor control.

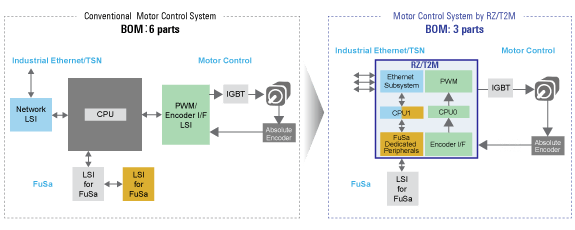

Based on the figure below, you can significantly reduce the number of components installed in a servo motor by utilizing the built-in functions of the RZ/T2M. First, you can incorporate the encoder interface, which enables accurate rotational position and speed detection required for servo motors, to reduce the number of external LSIs. Second, one of the two functional safety MCUs needed for mutual monitoring of functional safety can be eliminated by allocating one of the RZ/T2M's dual CPU cores for functional safety processing, and by using the peripheral functions dedicated to functional safety. Finally, you can use a Gigabit Ethernet switch that supports industrial Ethernet communication and TSN to reduce the number of external LSIs.

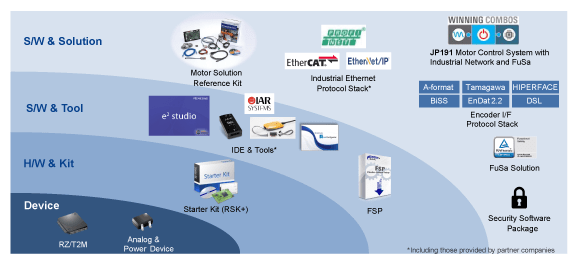

Next, we offer the following solutions for the smooth development of servo motors using RZ/T2M. The Renesas Starter Kit+ for RZ/T2M is an evaluation board suitable for initial evaluation. The Flexible Software Package (FSP) combines drivers for peripheral functions and OS, and a Graphical User Interface (GUI) that can be operated intuitively to enable users to use a smart configurator to generate driver software tailored to the user's application, making development easy. Renesas also provides sample programs for encoder interface protocols and protocol stacks for industrial Ethernet communication to reduce the development man-hours needed on these protocol implementations. By the end of 2022, we will provide functional safety solutions including "certified self-test software" for self-failure mutual diagnosis of the RZ/T2M, which is essential for microcontroller redundancy configuration, and "SIL3 system software kit," including SIL3-certified software with functions to separate multiple software allow users to obtain functional safety certification in as little as 1/3 of the current time needed. Man-hours spent on selecting peripheral components are further reduced by referencing to winning combination solution for Industrial Motor Control that optimally combines RZ/T2M and various Renesas devices.

Please refer to the RZ/T2M, Renesas Starter Kit+ for RZ/T2M, and Winning Combination Solutions for more details.