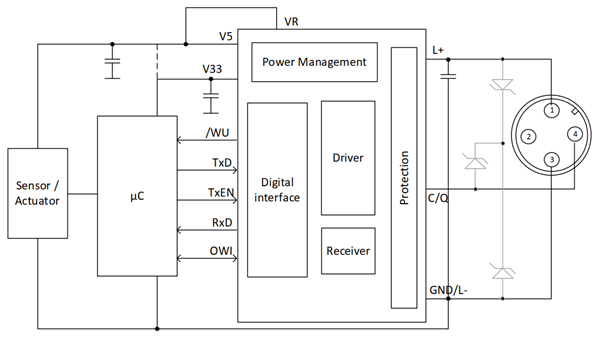

Industry 4.0 is progressively bringing intelligence from the PLC down to the sensing unit. The new generation of sensors and actuators are capable to return diagnostics information, trigger events, and even get their firmware remotely updated. The IO-Link protocol (IEC 61131-9) is getting a lot of traction within the factory and process automation sector. Industrial equipment supporting it is insured to utilize a flexible and well-maintained protocol benefiting from a large user and developer ecosystem. A typical Renesas IO-Link sensor/actuator consists of the RH4Z2501 IC, a MCU, and the sensing/actuator circuit:

The MCU is typically used for running a sensing application in parallel of the IO-Link software stack. The IO-Link stack interacts with the transceiver to exchange parameters via a UART interface (an interrupt to detect a wake-up signal from the Master) and a configuration digital interface like OWI.

Being active in the IO-Link community, Renesas is bringing a new silicon solution to the market that meets the latest IO-Link products requirements. The form factor in which new “smart sensors” are encapsulated is shrinking to save resources and manufacturing costs, it is now common to embed sensors in M8 or M5 type connectors. These new design requirements necessitate the use of more integrated ICs equipped with high robustness against EMC therefore limiting use of extra passive components.

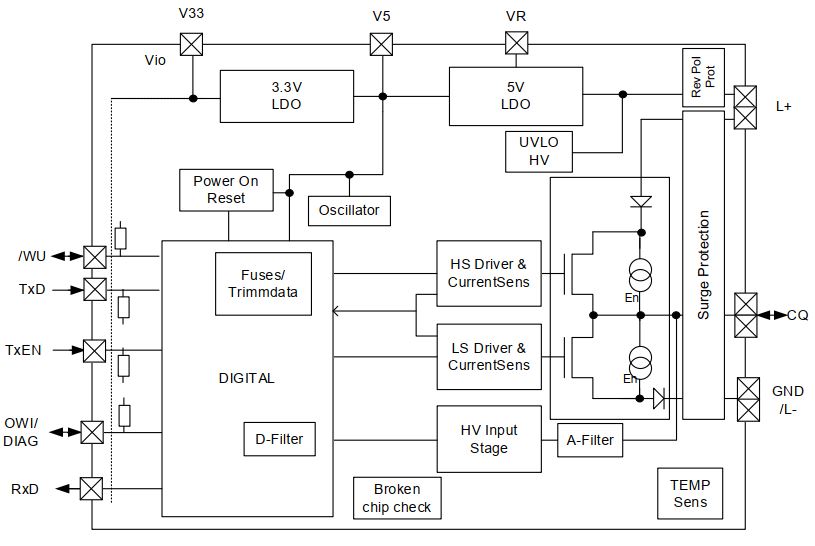

The RH4Z2501 device is an IO-Link compliant line driver/level shifter designed in a powerful CMOS mixed-signal technology that allows short supply voltage peaks up to 60V. It is available in DFN12 (3x3mm) or WL-CSP15 (2.45x1.65mm) packages and equipped with an integrated surge protection circuit to optionally skip Transients Voltage Suppressor (TVS) diodes in your design.

The PHY embeds 2 LDOs that can provide the needed 3V3 and 5V voltage rails to the MCU and to the sensing block. Its low RDSON of 2.5Ω helps to improve the power efficiency of the driver and therefore improve the thermal performance of the device:

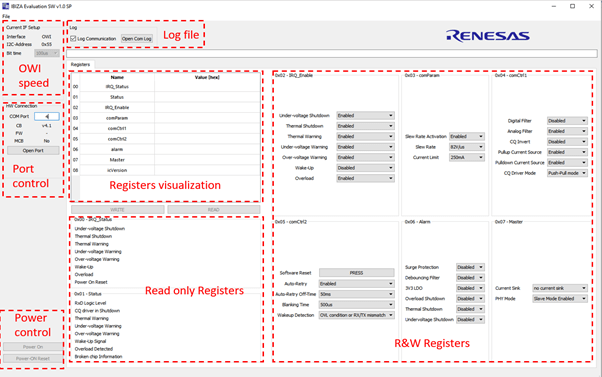

The PHY has 8 volatile memory registers (storing its current configuration) that can trigger alarms and store various diagnostic information. Those registers can be read and written via the OWI and are typically handled by the external MCU via a single GPIO in parallel with the IO-Link communication.

Renesas also provides a GUI to ease the evaluation:

Two of these registers are grouping the status information like voltage, temperature warnings and overload detection. The other six registers are typically used to test, fine tune, or change the operation mode of the transceiver. The RH4Z2501 can be set to operate as an IO-Link Device or a single channel IO-Link Master.

Start your evaluation by ordering the RH4Z2501-KIT. What are you waiting for? Integrate IO-Link into your own sensors today with the Renesas RH4Z2501!