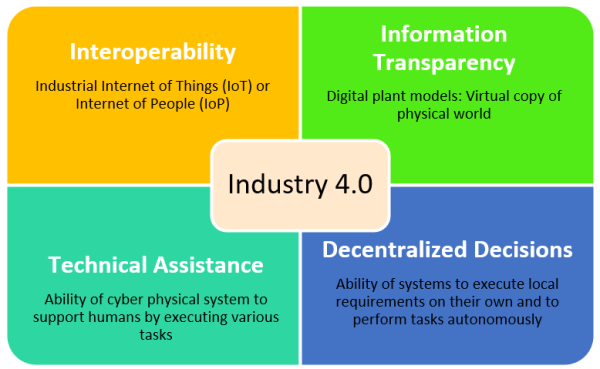

Industry 4.0 enables stakeholders to optimize facilities and increase productivity through interconnected industrial equipment and enhanced computation. It presents an excellent opportunity to assist stakeholders in utilizing converging technology to create a sustainable, human-centered future, where motors stand as vital contributors across industries. Figure 1 illustrates the process of identifying and implementing Industry 4.0, where the Internet of Things (IIoT) enables devices to link, creating a virtual duplicate of real-world data. This facilitates operators to visualize and analyze processes, enabling them to make decisions to autonomously perform tasks as efficiently as possible.

Figure 1. Design Principles of Industry 4.0

Induction motors (IM) play a crucial role in industrial domains as the main workhorse for maintaining efficient movement. Their proven reliability, versatility, and economic advantages make them the preferred choice for industrial applications. In the past, IMs were primarily used for single operating point applications, operating at rated torque and speed. However, advancements in motor control have expanded their usability across a wide range of torques and speeds, making them highly adaptable to different industry needs. Nowadays, almost all motion solutions have transitioned from pneumatic or manual operation to motorized systems.

The key requirements for motor controls across industries include:

- Maintaining stable operation across a wide range of loads.

- Ensuring quick and precise response.

- Supporting various position feedback sensors like encoders, resolvers, hall sensors, etc.

- Handling electrical noise and interference in feedback signals (current, voltage, temperature).

- Achieving high efficiency.

- Meeting the highest standards of reliability and functional safety.

- Being compact and lightweight.

- Supporting different industrial communication protocols such as UART, I2C, CAN, etc.

The induction motor operates on the principle of electromagnetic induction. The rotating magnetic field created by the stator excitation induces an electromotive force (EMF) in the rotor. As a result, currents flow through the rotor, producing torque and facilitating rotation. Thus, precise control of the stator excitation becomes crucial for effective induction motor control. Speed control for induction motors is typically classified into two main categories:

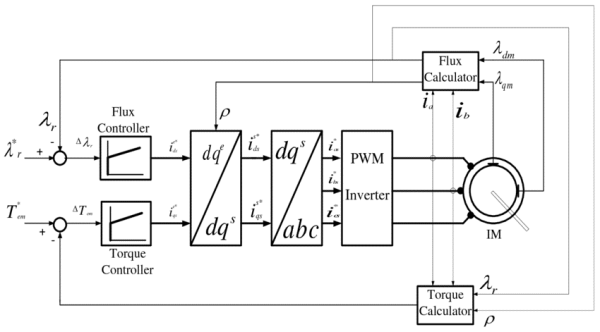

Scalar control. The majority of existing variable speed drive systems are low-performance drives that control the magnitude of the frequency of the stator voltage or current. The control is achieved by maintaining a constant magnetic field in the motor. The most commonly used scalar control method is Constant Volts/Hertz (V/f) control, wherein the magnitude of the stator voltage is adjusted in proportion to the frequency, thus keeping the stator flux constant in the motor. Although scalar control methods are relatively easy to implement, they are not suitable for applications involving transients on the load side. Below are shown the typical motor characteristics achievable with V/f control.

Image

Figure 2. Torque speed characteristic of IM with V/f control

Vector control. In contrast to scalar control, vector control of IM is based on field-oriented control (FOC) schemes. This method provides control of the phase and magnitude of vector quantities of the motor. Vector control drives are considered high-performance drives with control over instantaneous torque and magnetic field of the motor both under steady-state and transient conditions. Despite being computationally demanding, vector control outperforms scalar control, particularly in dynamic conditions.

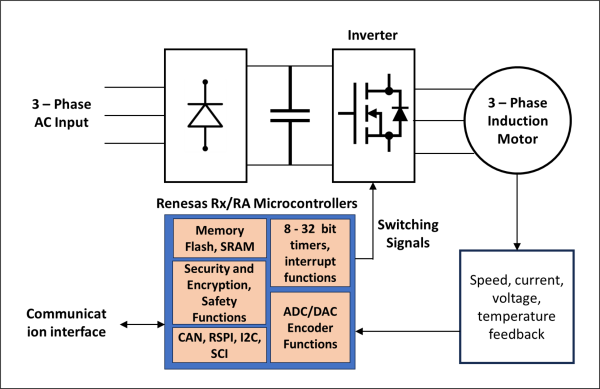

Vector control implementation involves estimation of rotor flux from either stator voltage or currents using flux observers which requires accurate sensing and fast computation.Figure 3. Vector control system for an induction motor with flux estimation

For modern applications, motors must operate on a wide operating range and under dynamic conditions, requiring vector control schemes to meet these demands effectively. Given the sensing and computational requirements, the careful selection of the appropriate microcontrollers (MCUs) is crucial for developing a robust induction motor control solution.

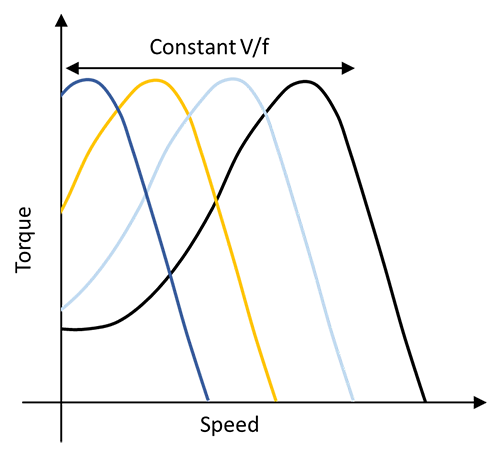

Figure 4. Typical block diagram of induction motor drive with Renesas microcontrollers

Figure 4 illustrates a typical induction motor drive and its major components. The induction motor drives receive power from a 3-phase AC input supply, which undergoes conversion into DC voltage through a rectifier unit. To reduce voltage ripple, DC link capacitors are placed across this output DC voltage. The DC voltage is then fed into the inverter, which converts it back into AC for the induction motor, based on the switching signals received by the MCU. The MCU, being the brain of the drive, plays a vital role in determining the performance and efficiency of the induction motor drive. For IM drive applications, the Renesas RA-T and RX-T MCU series have been meticulously designed with specific functions that help in the development of high-performance drive systems. Let's explore some key features of these MCUs below.

PWM generation. High-frequency PWM generation is critical for achieving lower THD in current waveforms and smooth control of any motor. RA-T and RX-T MCUs can support up to 200MHz frequency 3-phase complimentary PWM generation. These high-frequency PWM generations make them ideal for inverters with advanced GaN and SiC-based power switches, capable of operating on very high switching frequencies.

Trigonometric functions. Any advanced control scheme like vector control or other FOC control requires computation of torque and flux in real time which involves the implementation of many trigonometric functions. Renesas MCUs offer dedicated arithmetic units for trigonometric functions (TFU) which greatly reduce the computational time and increase the accuracy of the calculation. Other floating point operations required for motor control applications can be performed at a processing speed of 200MHz.

Feedback control. RA-T and RX-T MCUs have in-built 12/16-bit A/D converters. These ADCs can sample 3 currents simultaneously for accurate current control and switching state determination. To read feedback from encoders, dedicated phase counting modes ensure the capability to read encoder input up to 32-bit resolution.

Communication interface. Motor drives play a vital role within automation and processing industries as they are integral components of larger control systems and facilitate communication with master controllers and peripheral devices. Therefore, it is imperative for MCUs to be compatible with industry-standard communication protocols. Renesas MCUs can be integrated with larger systems seamlessly using communication interfaces such as SCI, CAN, I2C, RSPI, USB, and extended industrial protocols like Ethercat and Ethernet-IP.

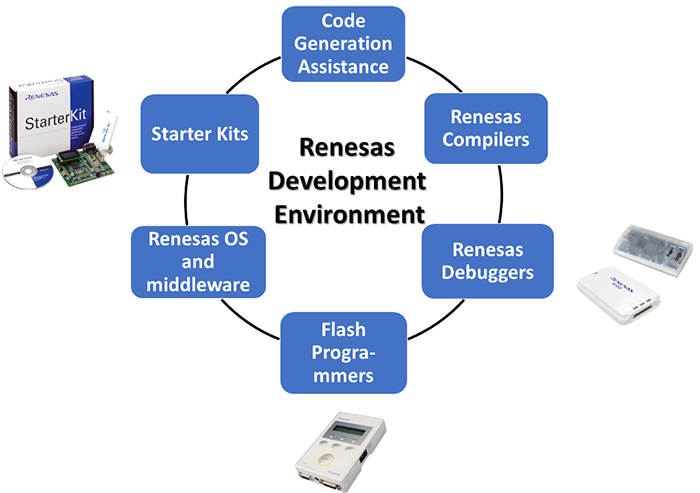

Renesas offers a complete development environment for rapid and reliable product development. The development environment provides dedicated solutions for every important stage of software and hardware development along with technical support provided by the Renesas team.

Figure 5. Renesas rapid development tools for motor control solutions

Recent times have witnessed an unprecedented acceleration in technological development, primarily driven by advancements in information technologies and digital computations. These developments are not mere incremental progressions but rather mark the inception of a new technological revolution known as Industry 4.0 (IR 4.0). At the center of this revolution lie the game-changing technologies of artificial intelligence (AI), machine learning, and data analytics.

In summary, the future is a seamless integration of the cyber-physical world. Considering the importance of motor controls for industrial applications, the new solutions have to complement these aspirations, and the capabilities of MCUs to play a vital role in achieving this goal. Renesas RX-T and RA-T MCU families have been developed with dedicated motor control features along with secure and fast data communication capabilities to meet the requirements of IR 4.0 and thus make an ideal choice for a robust industrial motor control system.