特性

- 宽输入电压范围:4.5V 至 60V

- 宽输出电压范围:0.6V 至 54V

- 轻载效率提高

- 具有脉冲跳频率功能的低纹波二极管仿真模式

- 可编程的软启动

- 通过 SR 软启动支持预偏置输出

- 可编程频率:100kHz 至 2MHz

- 外部同步

- PGOOD 指示器

- 强制 PWM

- 自适应直通保护

- 无外部电流感测电阻

- 使用较低的 MOSFET rDS(ON)

- 完整的保护

- 过电流、过电压、过热、欠压

- 无铅(符合 RoHS)

描述

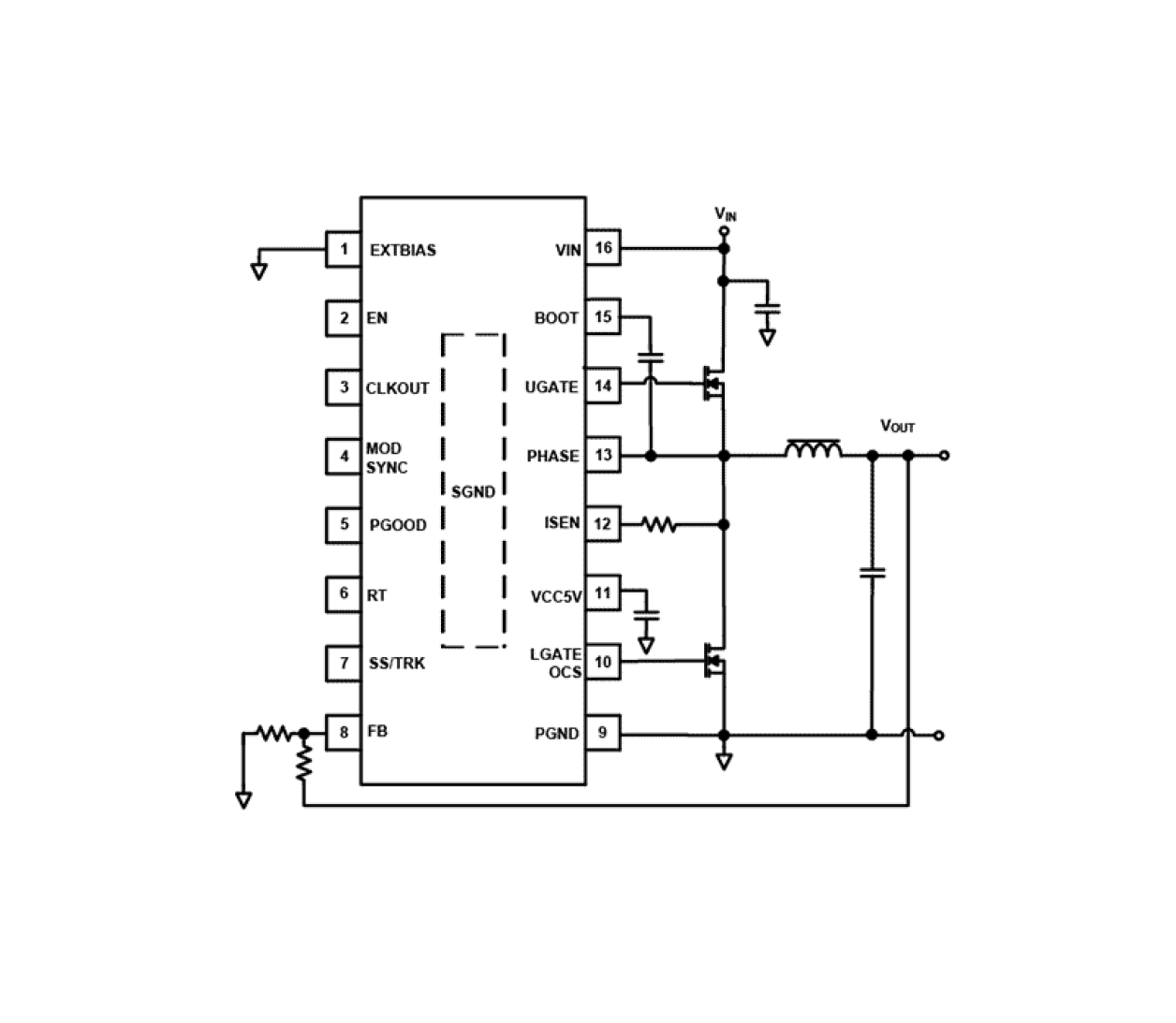

ISL8117 是一款同步降压控制器,用于生成 POL 电压轨和偏置电压轨,适用于工业和通用领域的各种应用。 其宽输入和输出电压范围使其适用于电信和汽车售后市场应用。 ISL8117 采用谷值电流调制技术,以最少的组件数量实现轻松的电源设计,并提供全面保护,防止意外事件发生。 ISL8117 具有可编程软启动和使能功能,且配备电源良好指示器,便于实现电源轨排序和其他内务管理要求。 在理想情况下,只需 10 个外部元件就能设计出完整的电源电路,可提供 OV/OC/OT 保护,封装为节省空间的 16 Ld 4mmx4mm QFN 或易于组装的 6.4mmx5mm 16 Ld HTSSOP。 两个封装均采用 EPAD 提高热耗散和抗噪声能力。 低引脚数量、更少的外部元件和默认内部值,使 ISL8117 成为简单电源设计快速上市的理想解决方案。 ISL8117 使用内部环路补偿和单电阻设置来实现工作频率和过流保护等其他功能。 该器件具有 VIN 前馈的电流模式控制,即使内部补偿固定,也能满足各种应用需求。 轻载时独特的 DEM/脉冲跳频模式可显著降低待机功耗,并在不同负载水平下保持稳定的输出纹波。

产品参数

| 属性 | 值 |

|---|---|

| Outputs (#) | 1 |

| Topology [Rail 1] | Buck |

| Input Voltage (Min) [Rail 1] (V) | 4.5 |

| Input Voltage (Max) [Rail 1] (V) | 60 - 60 |

| Output Voltage (Min) [Rail 1] (V) | 0.6 |

| Output Voltage (Max) [Rail 1] (V) | 54 |

| Output Current (Max) [Rail 1] (A) | 30 |

| Switching Frequency Range (Typical) (kHz) | 100 - 2000 |

| Qualification Level | Standard |

| Temp. Range (°C) | -40 to +125°C |

| Simulation Model Available | iSim |

应用方框图

| 100W/140W USB-C 和 USB PD 电源 具有多路输出、更高效率和高性价比设计的 USB-C 和 USB PD 电源。 |

| 100W 多路输出 USB PD 电源适配器 高性能 USB PD 电源适配器,可为多个电子设备高效充电。 |

| 人工智能监控摄像机 具有 DRP-AI 功能的 AI 监控摄像机可通过 4K 成像和低功耗提高安全性。 |

| 家用水泵 智能水泵系统,耗电量低、噪音小、安全性高,可实现高效运行。 |

| 电动自行车系统 集成先进微控制器、电源和 BMS 器件的完整电动自行车系统,可延长续航里程并提升操控性能。 |

| 电力线语音通信 瑞萨电子的 PLC 调制解调器技术可通过低压电力线实现高效的语音传输。 |

| 视频 IP 电话 视频 IP 电话设计,具有 Hi-Fi 高保真音频、降噪、触控显示屏和多功能连接功能。 |

| 48V 无刷直流(BLDC)电机位置控制 高效的无刷直流(BLDC)电机系统,具有精确控制、快速唤醒和无缝组件集成功能。 |

当前筛选条件

筛选

软件与工具

样例程序

模拟模型

Learn how the ISL8117 buck (step-down) PWM controller reduces design time and takes up less real estate on the board than competing devices.

ISL8117 is a high voltage controller that gives the power supply designer an opportunity to optimize their design for cost, size and efficiency. (Part 1)

The ISL8117 evaluation board features probing points to monitor different signals such as input voltage, output voltage, and output response. (Part 2)