Brushless DC (BLDC) motors are electric motors that are powered by direct current. They are known for their high efficiency compared to traditional brushed motors due to the lack of mechanical brushes. This offers improved reliability, a longer lifespan, and minimal maintenance. However, these motors require a precise control algorithm to switch the current between the windings. Renesas has pioneered when it comes to providing precise control algorithms in both hardware and software to our customers. There are several algorithms to drive these BLDC motors, such as vector control (field oriented control), trapezoidal control, or others, based upon a sensor or sensorless approach, depending on the application and the control requirement.

In this blog, we focus on detecting startup anomalies for BLDC motors using the sensorless approach.

Why Use a Sensorless Approach in Field Oriented Motor Control?

There are several advantages to using a sensorless approach. First, we increase the motor lifespan by reducing the mechanical complexity related to the sensors; second, we avoid additional sensor maintenance costs; and finally, we reduce the BOM. However, these advantages come at a cost when it comes to motor startup and low-speed precision. Thus, we decided to improve the startup of BLDC motors by training an AI model that can detect any anomaly related to the motor startup.

How to Detect a BLDC Motor Startup Anomaly?

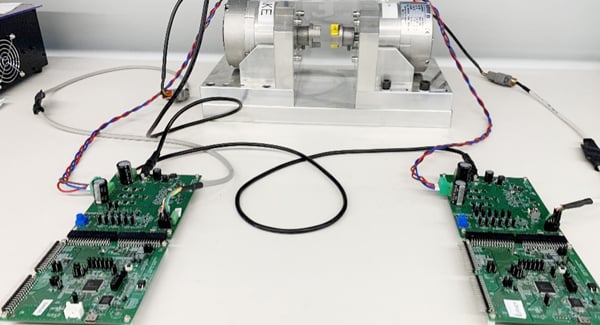

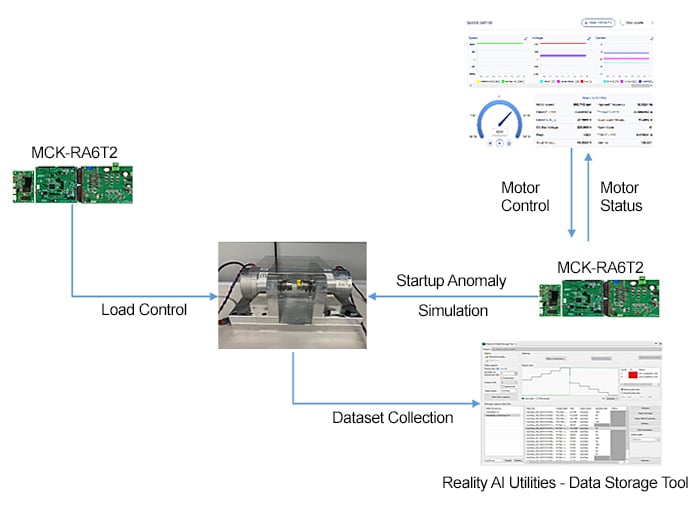

Use an AI model to solve an anomaly relevant to the BLDC motor startup sequence problem with a motor bench containing two motors. The first motor is being used to create the startup anomaly, while the other motor is simply acting as a load. The beauty of this motor bench is that it has the capacity to change the load applied to the motor in real time. Each motor is being controlled via the Renesas RA6T2 motor control kit (MCK-RA6T2). The MCK-RA6T2 consists of the MCB-RA6T2 CPU unit and the MCI-LV-1 low-voltage inverter. The setup looks as follows:

The motor bench is controlled by a graphical user interface (GUI) from a local PC that is connected to the MCK-RA6T2. When the motor parameters are incorrect, the motor will try to start, but it will stall if there is a connected load. However, in this case, the GUI does not show that the motor has stopped; instead, it gets the feedback that the motor is always running.

An AI model can be trained to detect the pattern of the motor startup and detect any anomaly. First, we collect a dataset from the motor, which includes the current and the voltage measured by the inverter. Once the AI model is well trained, it can distinguish the different patterns in the electrical current from the motor and provide the exact information about the current startup of the motor. This will allow the GUI to provide an accurate result of the startup status of the motor.

AI Model Development

The Renesas AI Center of Excellence (COE) team has developed an AI model to detect anomalies. We simulated this anomaly using the above motor bench by modifying the startup parameters, which can happen if the user is not aware of the correct parameters to build a successful startup sequence.

To develop the AI model, we have collected a dataset from the motor bench in Figure 2. The dataset describes both situations that can affect the motor—the first one when the motor is attached to a load, while the other is without any load attached to the motor.

There are four situations that the model can detect:

- Normal behavior when the motor has an attached load

- Anomaly behavior when the motor has an attached load

- Normal behavior when the motor has no load

- Anomaly behavior when the motor has no load

All these cases need to be evaluated and tested with our developed AI model to be sure that we can detect any startup anomaly. We have collected a dataset for each of the above cases and trained an AI model for all of them.

Dataset Collection and AI Model Training

The dataset has been collected using the data storage tool. This tool is part of the Reality AI Utilities integrated into the e2 studio. It will capture the data from the MCK-RA6T2 and will upload the collected data directly to Renesas' Reality AI Tools®. Using this cloud tool, an AI model can be trained and optimized for a Renesas MCU, minimizing the footprint for RAM and Flash. Once the model is well-trained, it is tested on an independent dataset to check the model's performance. If the performance of the model is correlated with the training results, we will deploy the model on the MCK-RA6T2 and conduct another test on the motor itself.

The accuracy of the model is directly collected from the field, resulting in 576 bytes of RAM consumption of the model, and 4146 bytes of Flash.

By using Edge AI and integrating this model directly into our motor control firmware, we will be able to detect a startup anomaly that is affecting the motor in real time.

For more information and/or to start your evaluation with Renesas, check out our Motor Control Kit (MCK-RA6T2) and request a demo of the Reality AI Tools.