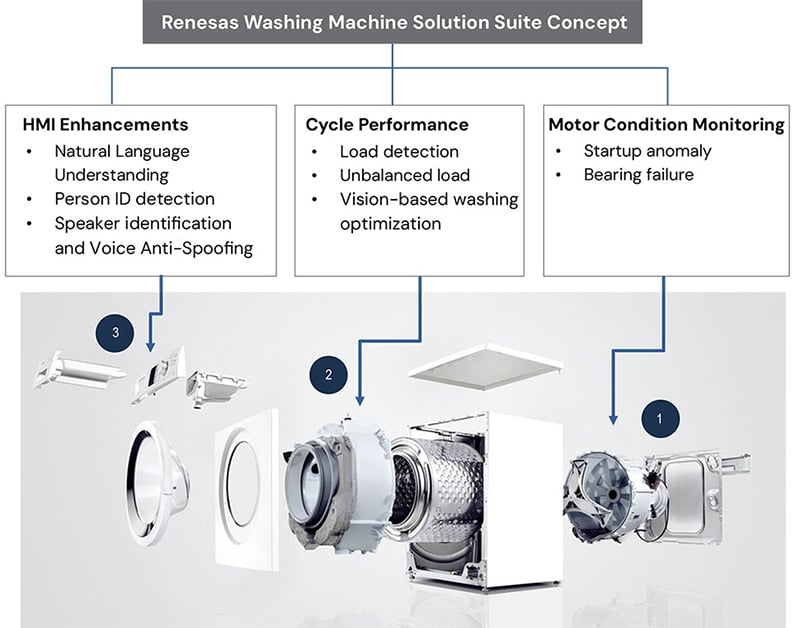

洗衣机是现代生活中不可或缺的一部分,也是自动化洗衣护理的基石。 尽管他们在过去二十年中在更高效地使用能源方面 取得了重大进展,但挑战仍然存在。 用户经常为在众多控制策略的循环作用而无法获得有效的判断 而苦恼 ,并且由于磨损、不平衡负载和控制效率低下,电机可靠性仍然是一个问题。 需要进一步的进步来提高可靠性、可持续性和能源性能——最好是通过不需要额外传感器的软件驱动创新。 瑞萨电子推出了基于软件的智能洗衣机概念,以提高两个关键领域的性能:

- 用户界面: 升级人机界面 (HMI),以获得更直观、更简化的用户体验。

- 电机可靠性:在软件中实现 状态监测层,通过实时检测磨损、不平衡和控制效率低下 的状态 来提高耐用性和效率,从而延长产品使用寿命并降低维护成本。

这两项增强功能均由嵌入式 AI 模型提供支持,作为瑞萨硬件上的软件组件实现。 这种方法可以在不增加硬件复杂性的情况下实现更智能、更高效的设备。

电机状态监测

作为瑞萨电子提高洗衣机可靠性的软件驱动方法的一部分,电机状态监测发挥着至关重要的作用。 通过将人工智能模型直接集成到设备中,该系统可以实时检测关键电机异常,而无需额外的传感器。 这包括识别启动不规则性、检测不同的负载条件、识别不平衡负载以及预测潜在的轴承故障。 这些见解最终通过优化整体性能来提高机器质量并提升用户体验。

启动异常检测

由于电气不平衡或重负载,可能会发生启动异常,甚至在洗涤周期开始之前就扰乱电机行为。 瑞萨电子的 AI 算法分析来自 BLDC 电机控制 的系统参数,以检测机器启动阶段的这些异常情况。 这种早期检测有助于防止损坏电机、滚筒或电子设备。 此外,该系统还提供更清晰的错误消息和主动支持通知,从而加快修复速度、减少技术人员访问次数并减少用户停机时间。

轴承故障

轴承是所有旋转系统中必不可少的部件,但它们会逐渐退化。 它通常始于微妙的高频异常。 轴承问题通常不会被注意到,直到它们引起可听见的噪音或机械中断,此时已经发生了重大损坏。

瑞萨电子的无传感器 AI 模型可监控电机系统参数,以便及早检测轴承磨损。 通过识别机械负载和摩擦的变化,该模型可以通过软件更新实现预测性维护,无需添加硬件。 这种方法提高了机器的可靠性并简化了制造商的集成。

循环性能

负载检测

准确检测衣物重量对于优化水、洗涤剂和循环持续时间至关重要。 瑞萨电子的 AI 模型通过分析电机系统参数和预测滚筒中衣物的重量,实现 无传感器负载检测 。 这导致:

- 更高效、更环保的洗涤周期

- 减少水和洗涤剂的使用

- 提高洗衣质量

- 更短的循环时间

不平衡负载

当不同重量的衣物分布不均匀时,会产生不平衡的负载,影响机械和作稳定性。 这可能导致:

- 振动增加: 重量分布不均匀导致滚筒偏离中心旋转,产生过度振动。 振动传递到电机和其他机械部件,增加磨损,从而损坏滚筒轴承。 如果这种振动达到系统的共振频率,可能会对机器造成结构损坏。

- 更高的能耗: 电机补偿不平衡,导致功耗增加和效率降低。

为了解决这个问题,我们开发了一种无传感器人工智能模型,可以检测不平衡负载和轴不对中。 该模型的运行方式与我们现有的负载检测和启动异常检测系统类似,不需要额外的硬件组件。

- 纯软件实现: 该模型利用现有系统数据,不需要额外的传感器或 BoM 成本。

- 增强的可靠性: 及早发现不平衡负载使系统能够采取纠正措施(例如,重新分配负载或调整旋转循环),从而提高机器寿命和用户满意度。

基于视觉的循环优化

瑞萨电子将人工智能更进一步,通过在滚筒 内放置视觉传感器(例如摄像头)来实现基于视觉的循环优化。 这使我们能够:

- 识别不同类型的纺织品(例如,棉、羊毛、合成纤维等)

- 通过衣物颜色检测优化洗涤策略

- 相应地调整消耗的水量、温度、洗涤剂和滚筒速度

该解决方案概念由嵌入在洗衣机中的物体检测模型提供支持,该模型经过优化以识别衣物。 将 纺织品在放入滚筒之前进行预过滤的 策略可以进一步用于优化 工业用例。

人机界面增强

重新定义洗衣机中的人机界面 (HMI) 是一项复杂的任务,需要嵌入以用户为中心的智能功能,以提高便利性和安全性。 瑞萨电子通过 支持高级自然语言理解 (NLU) 的嵌入式 AI 模型实现了这一转变,使作更加直观和易于访问。 人员 ID 检测允许系统识别单个用户并应用个性化设置,而说声音识别与语音反欺骗相结合,确保只有授权用户才能发出语音命令,尤其是在共享或工业环境中。 在以下部分中,我们将探讨这些功能在无云环境中如何可行:

说话人识别和自然语言理解

设置洗衣机有时可能具有挑战性,尤其是当不清楚哪个程序最适合您的衣物、哪些参数需要调整或旅行时界面使用不同的语言时。 一种创新的解决方案是启用语音命令,由一系列嵌入式人工智能模型提供支持。

首先, 语音反欺骗模型 识别授权运营商。 然后, 语音命令识别模型 允许操作员简单地说明衣物类型和所需的洗涤参数。

系统提取并与操作员一起验证这些信息,然后自动选择最佳设置。 自然语言理解的最新进展使其能够在边缘有效运行,只需极低的 RAM 和 ROM 要求,即可轻松将软件直接集成到现有设备硬件中。

使用面部 ID 检测改善用户交互

人脸识别技术提供了一种强大的方式来个性化和保护现代洗衣机的用户体验。 通过 嵌入式人脸检测模型识别用户,系统可以自动加载自定义配置文件,例如首选洗涤程序和周期设置,而无需手动输入。

除了个性化之外,这种方法还增强了安全性和访问控制:

- 儿童安全: 防止对机器设置进行未经授权的更改。

- 工业用途: 限制授权人员装卸衣物的通道。

为了确保隐私和数据保护,人工智能模型完全嵌入洗衣机中,没有云连接。 所有用户数据都在本地存储和处理,保持安全、无缝的体验。

这种基于人工智能的智能洗衣机解决方案概念凸显了边缘人工智能在家电市场的变革潜力,使这些机器更加可靠、高效和环保。

瑞萨电子 AI/ML 通过可扩展、边缘优化的 AI/ML 解决方案为下一代 AI 技术提供支持,从而加速跨行业的智能决策。

准备好将您的智能家电创意变为现实了吗?

访问 www.renesas.com/ai 访问您需要的一切,从目标设备和 AI 参考平台到应用示例,以加速智能嵌入式系统的开发。 这些实践资源将帮助您立即开始使用瑞萨电子的可扩展 AI/ML 技术构建智能的边缘驱动解决方案。