特性

- 对传感器偏移、灵敏度、温度漂移和非线性进行数字补偿

- 几乎可适配所有全桥或半桥传感器

- 模拟增益 200 倍,使用数字变焦选项可支持低至 1mV/V 量程的传感器

- 输出选项:比例式 12 位模拟电压输出(如 5-95% 或 10-90%),带自由可调钳位功能或 ZACwire™ 数字单线接口(OWI)

- 温度补偿:内部或外部二极管、桥路外接串联电阻或 RTD

- 通过内部电压实现传感器偏置

- 所有模块引脚(VDDE、VSSE 和 AOUT)均可承受最高 40V 的高压并具有反极性保护

- 最大电源电流:7mA

- AOUT 短路保护

- 通过用户定义寄存器实现可追溯性

描述

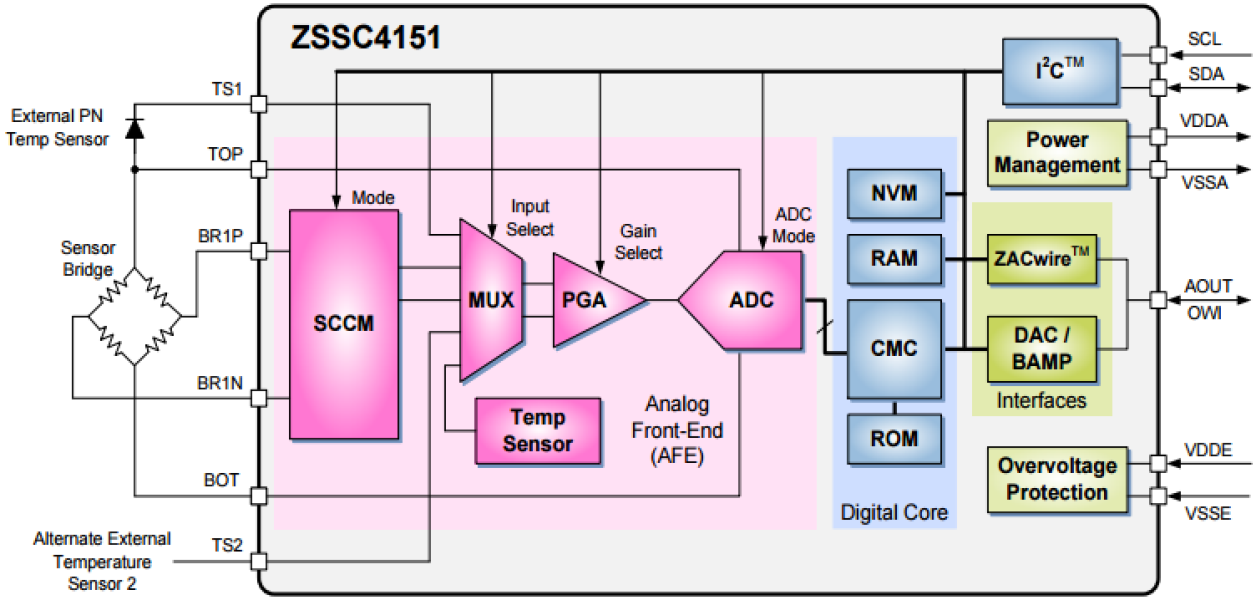

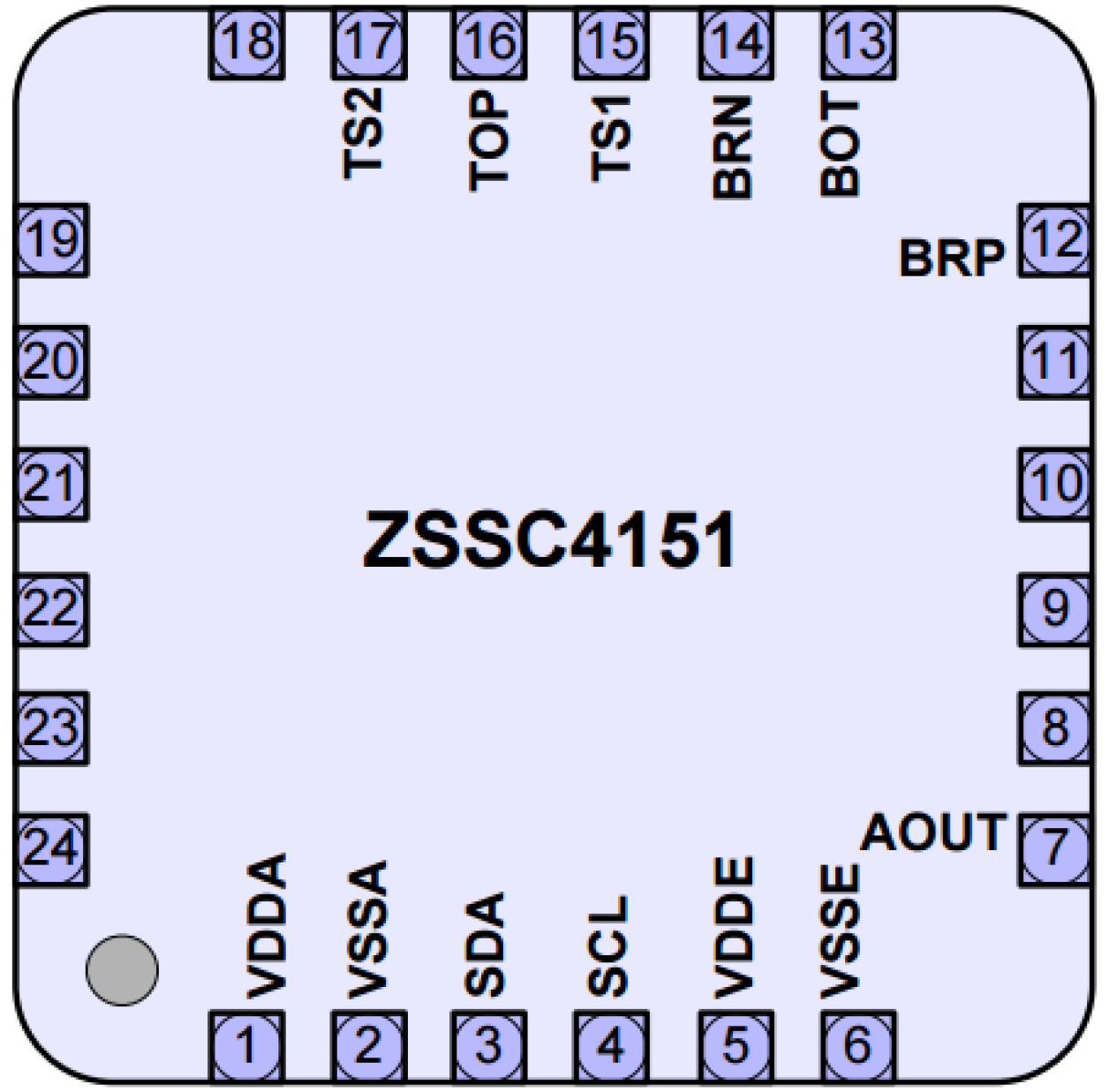

ZSSC4151 是一款 CMOS 集成电路,专用于电阻电桥传感器信号的放大及传感器特性化校正。 该器件通过内部 16 位 RISC 微控制器运行校正算法,实现传感器偏移、灵敏度、温度漂移和非线性度数字补偿。所有校正系数均存储在集成 EEPROM 中。 ZSSC4151 几乎可适配所有电阻电桥传感器类型。 测量值可通过模拟电压输出端和可选的数字 I2C 接口或 ZACwire™ 接口(也称为单线接口 (OWI))提供。 数字接口可用于简单的 PC 控制校准程序,将整套校准系数编程到片载 EEPROM 中。 ZSSC4151 和校准设备可进行数字通信,因此噪声灵敏度大大降低。 数字校准有助于保持较低的装配成本,因为不需要外部设备或修整。

产品参数

| 属性 | 值 |

|---|---|

| Function | Resistive SSC |

| Automotive Qual. | Yes |

| Supply Voltage (V) | 4.5 - 5.5 |

| Input Type | Single-bridge |

| Interface | Ratiometric Voltage, ZACwire™, I2C, Switch Output |

| Adj. Analog Gain | 1 - 200 |

| Resolution (bits) | 18 |

| Sample Rate Max (KHz) | 2.8, 3.4 |

| Temp. Range (°C) | -40 to +150°C |

当前筛选条件

筛选

软件与工具

样例程序

模拟模型

The ZSSC4151 is a CMOS integrated circuit for highly accurate amplification and sensor-specific correction of resistive bridge sensor signals. Digital compensation of sensor offset, sensitivity, temperature drift, and non-linearity is accomplished via an internal 16‑bit RISC microcontroller running a correction algorithm, with calibration coefficients stored in an integrated EEPROM.

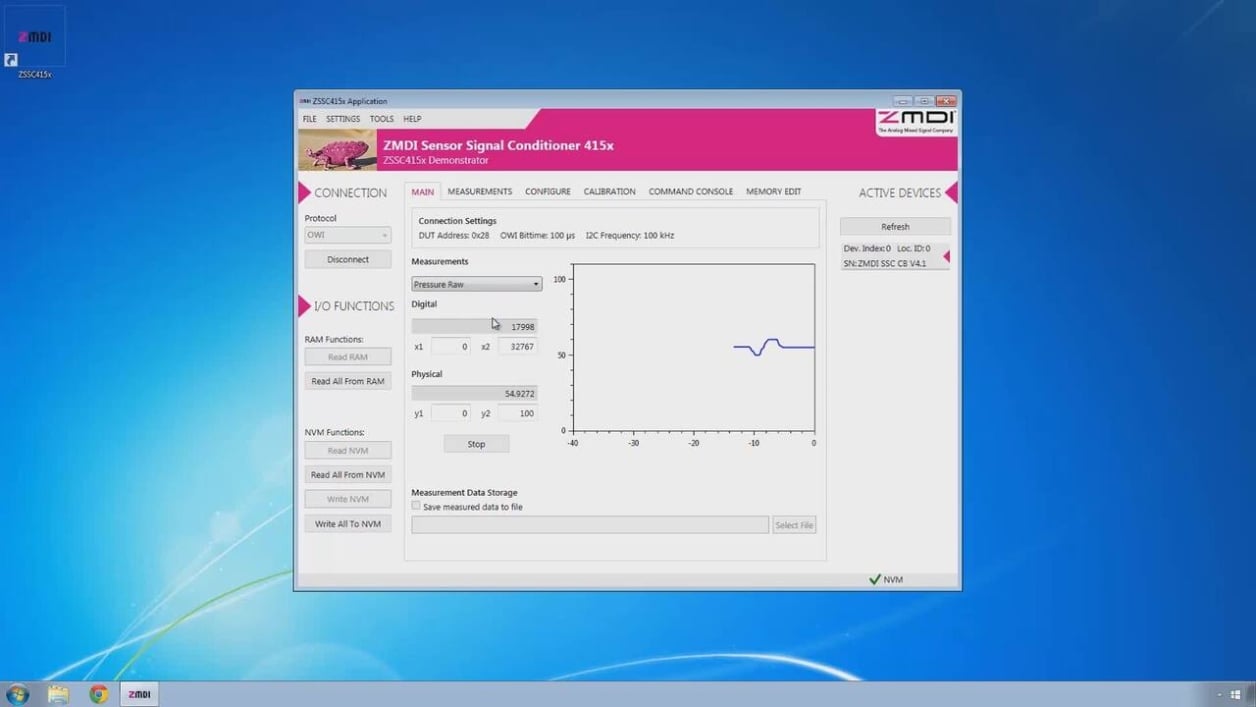

A brief introduction and overview of IDT's (acquire by Renesas) sensor signal conditioner evaluation kits. Evaluation kits generally consist of three parts: a communication interface board, a device board, and a sensor simulator board - all connected together. A sophisticated software GUI accompanies the kit, enabling an engineer to learn how to use the part rapidly, do quick prototyping, and practice calibrations.

Presented by David Grice, applications engineer at IDT. For more information about IDT's sensor signal conditioner products, visit the Sensor Signal Conditioner page.