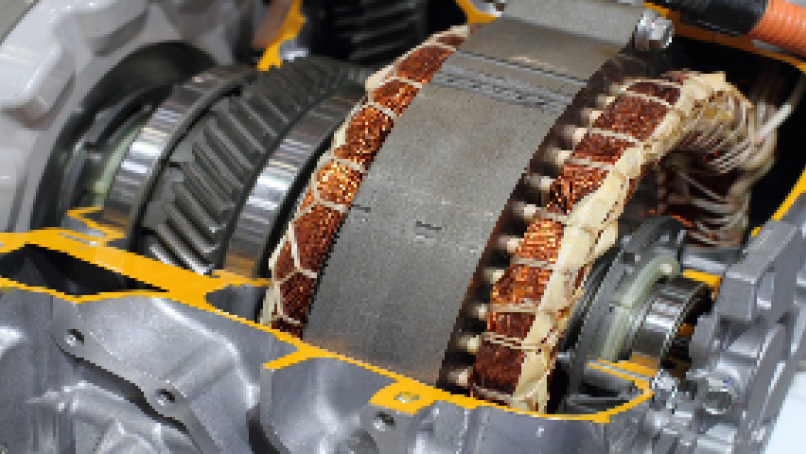

High-voltage motor control evaluation and development must be conducted in a safe environment to reduce the risk of electric shock and burns faced during development and create a safe evaluation environment. Renesas released the MCI-HV-2-3PH inverter board to enable motor control evaluation for industrial three-phase 200V induction motors/BLDC motors, and support customers in creating a safe motor control development environment.

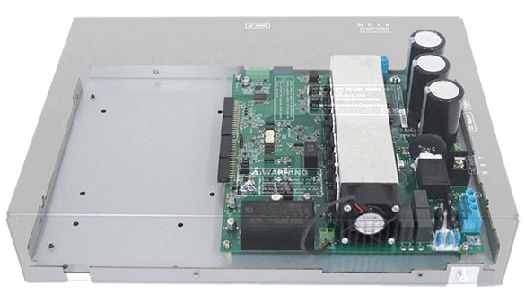

Create a Safe Evaluation Environment

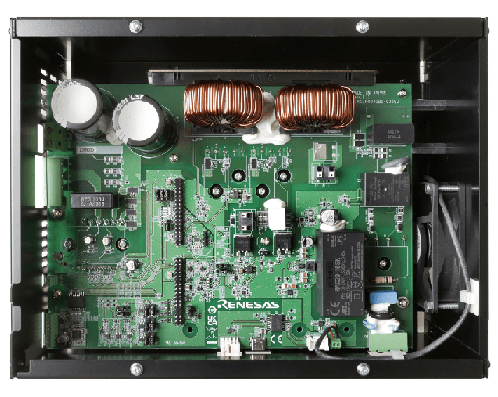

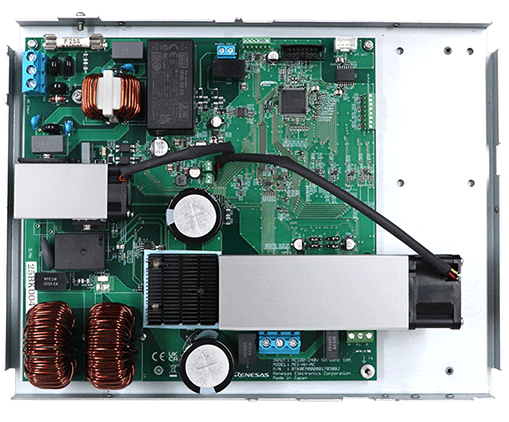

Renesas' high-voltage motor control evaluation inverter board is covered with a casing and fixed with screws, reducing the risk of electric shock during evaluation. The CPU board and communication board with the PC can also be set inside the casing, making it portable and convenient to carry. Additionally, it is equipped with various protection functions such as overcurrent detection, overvoltage protection, and over-temperature detection. Please check the MCI-HV-2-3PH Flexible Motor Control Inverter Board product page for more details.

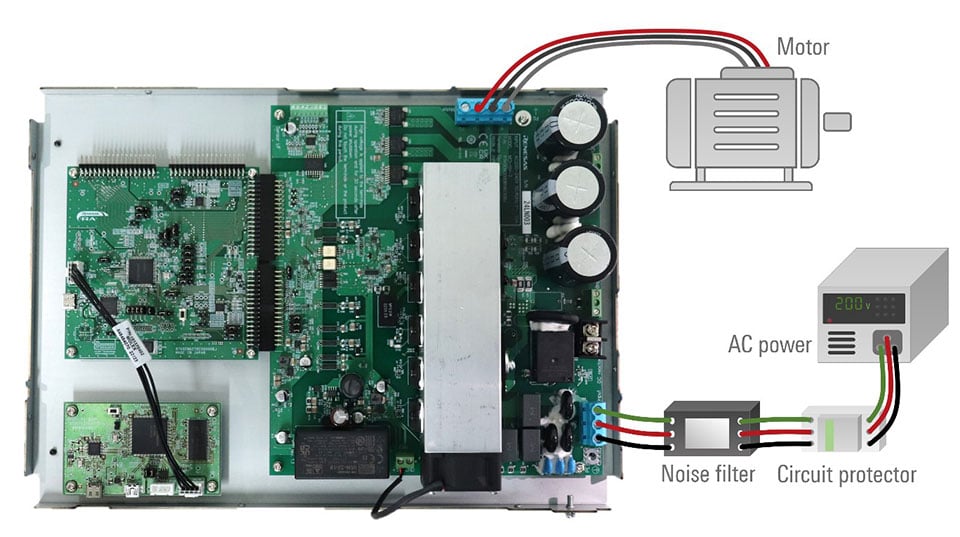

Lower the Hurdle to Start Evaluation – Simple Setup in Two Steps!

First, connect the CPU board and communication board required for evaluation to the inverter board. It is possible to connect and store each board inside a casing that is optimized for desktop evaluation. Next, connect the noise filter and motor. This allows you to immediately start the evaluation. The compact casing also has a fan to dissipate the heat generated during evaluation, preventing heat buildup inside the casing and enabling long-term evaluation.

Easy Debugging with the Motor Support Development Tool

Renesas' high-voltage motor control solution utilizes the Renesas Motor Workbench development support tool to perform motor parameter estimation, motor control program debugging, analysis, and tuning. Connecting the communication board (MC-COM) to the CPU board, users can read and write the values of global variables in the program in real-time on the PC screen.

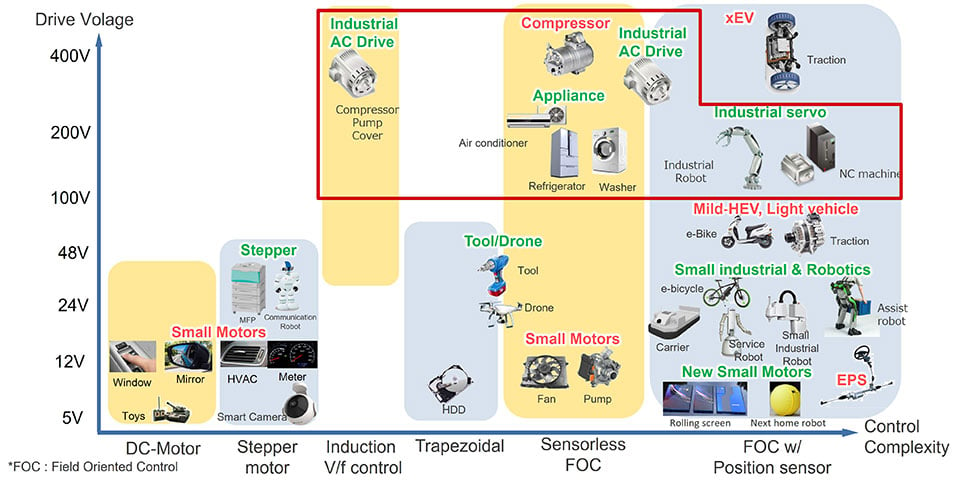

Renesas provides scalable high-voltage solutions to support rapid development needs. Renesas' high-voltage motor control evaluation kits include two products—MCI-HV-1 for home appliances and MCI-HV-2-3PH for industrial applications with three-phase input. Additionally, an AIR-CON-ODU-REF reference design for dual motor control with interleaved PFC for air conditioner outdoor units is available on our website.

The MCI-HV-1 solution enables easy evaluation of high-voltage (AC100V/AC200V) BLDC/induction motor control. We provide various sample programs and application notes that implement control methods.

The MCI-HV-2-3PH solution aims to efficiently conduct motor control evaluation and development during product development, incorporating industrial high-voltage motors with three-phase AC200V systems.

The AIR-CON-ODU-REF solution is a reference design for the control and evaluation of two motors, specifically the compressor and fan motor in air conditioner outdoor units. Design information and sample code can be downloaded from renesas.com.

To conduct high-voltage motor control evaluations in a safe environment, please consider Renesas' solutions.

For more information about Renesas' motor control, visit the Advanced Motor Control Technology Solutions webpage.